03 мар Lean Development Methodology: Principles, Advantages, And Implementation

Further processing is incompetent or pointless extra process steps that add no worth to the development Digital Twin Technology process. As Soon As we perceive all seven wastes, we ought to always have the power to identify the wastes in the course of, irrespective of Business. Once you can determine it, you’ll have the ability to remove it and therefore enhance your effectivity, productiveness, and revenue. Lean mapping may be carried out on the project degree, to determine a process for an individual project, or you can map a extra common process that may be adopted by multiple groups or initiatives. Generally a broader, cross-project map can present synergies or savings that arise in the connections between your projects.

By decreasing unnecessary activities and optimizing the development cycle, it might possibly assist decrease growth prices. There is always a process that could be improved, and there will always be steps in project and product development that waste money and time or don’t deliver worth. If you’re looking to dive into the history of lean agile, Lean Enterprise Institute Inc., founded in 1997 by James P. Womack, PhD, is a leading useful resource for lean methodology.

This guide explains their advantages, value implications, safety, and efficiency to assist you find the perfect cloud answer. Selecting the proper Behaviour-Driven Improvement (BDD) framework is essential to enhancing collaboration and software quality. This guide explores well-liked frameworks, choice criteria, and suggestions for smooth adoption. Sure, Lean Improvement ideas may be utilized to varied industries and businesses. Lean methods have been efficiently implemented in manufacturing, healthcare, service sectors, and extra.

Faqs Associated To Lean Software Development (lsd)

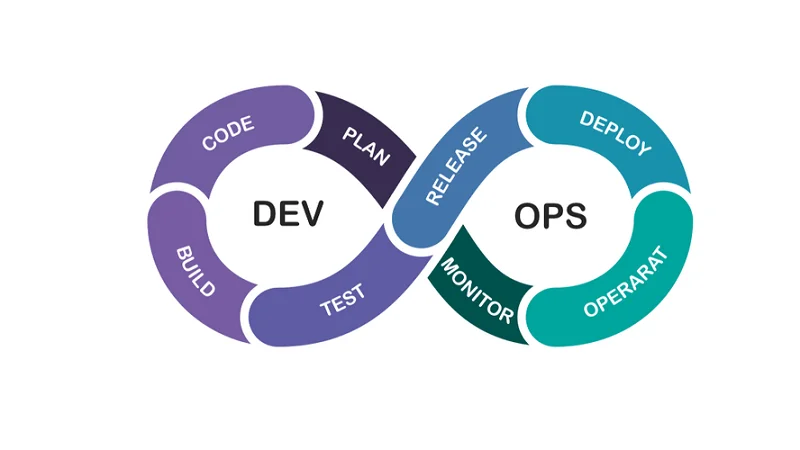

It aims to help individuals and groups work better through lean pondering and practices. These methodologies complement each other in their aim to ship quality and worth to clients. DevOps breaks down silos to combine the event and operations teams. Jira can help software program groups stay lean and deliver more buyer worth. Contextual insights empower groups to construct and train muscular tissues to constantly study and improve their means of working.

A circulate state is when the group is in a groove and work is transferring smoothly, so much so that we don’t discover the passage of time. For example, the mobile phone was a Needed product in the Nineties as a end result of it was on the vanguard of know-how. There is enough information in the public domain in order that even small firms can make a good mobile phone. Roadmunk is the most effective roadmapping device for building and communicating your product strategy.

In fact, in today’s business context, effectivity and pace in creating the merchandise that the purchasers want have turn out to be a matter of life and dying for any group. Lean Growth emphasizes effective communication via practices similar to every day stand-up meetings, visible management tools, clear documentation, and fostering a tradition of open and clear communication. These methods assist overcome poor communication and improve collaboration within improvement teams.

By prioritizing the delivery to ensure high quality of defect-free software, teams can cut back rework and enhance customer satisfaction. In product administration, lean is about making use of a scientific experimentation method to find the right solutions to the best issues faced by customers. Lean Software Development (LSD) is an agile framework used to streamline and optimize the software improvement process. It may be referred to as the Minimal Viable Product (MVP) strategy as these ways of thinking are very similar since both intend to hurry up growth by focusing on new deliverables. LPPD is a robust system for developing new services, as well as the processes wanted to supply and deliver them.

Lean Development emphasizes mapping and analyzing the value stream, which represents all the steps involved in delivering value to the customer. By identifying and eliminating non-value-adding actions, Lean Development https://www.globalcloudteam.com/ optimizes the value stream to maximise effectivity and customer worth. As An Alternative of making early, irreversible selections, Lean Growth advocates for delaying commitments until the final accountable moment. This allows groups to gather extra info, incorporate buyer feedback into lean thinking, and make informed decisions aligned with evolving requirements. You can contact our staff or watch a demo to learn extra about our tools and comply with our weblog for the most recent content on Jira, agile, lean, and the development process.

The 7 Rules Of Lean Software Program Growth Defined

Lean software improvement teams experiment and study by way of any outcome, challenge the established order, and fine-tune the team’s capability to reply to sudden situations. Tools like Kata, set-based design, and A3 assist grasp these capabilities. These three check-ins ensure 1) product-market fit (Definition check-in), 2) proof of idea created (Design check-in), and 3) verify product function set and go-to-market plan (Development check-in). Typically what is lean development these occasions take place over several days, but they’re often a single day in period.

Deliver As Fast As Possible

- This means having metrics and KPIs that consider how effective and environment friendly lean has been in the group, both culturally and operationally.

- Quality isn’t an afterthought in Lean; it’s in-built from the beginning.

- One of the wholesome ways towards integral structure is refactoring.

The product growth course of begins with a transparent understanding and definition of the issue or alternative. It involves gathering relevant information by conducting market research, participating with the audience to determine their ache factors, and discovering insights. A concise and exact downside assertion is essential to set the direction of the lean development course of. Optimizing the whole means specializing in improving the whole product growth process, all the finest way from the preliminary concept to delivery and past, to upkeep and operation. Nevertheless, it also means looking at your software program as a product and ensuring that it is complete and meets the needs of the client.

Via ongoing experimentation, employees and managers learn by innovating in their work — be it bodily or information work — for more and more better high quality and move, less time and effort, and lower cost. Due To This Fact, a corporation characterized by lean apply is very adaptive to its ever-changing environment when compared to its friends due to the systematic and steady studying engendered by lean considering and practice. Lean thinking needs to be understood nicely by all members of a project, before implementing in a concrete, real-life state of affairs. „Think huge, act small, fail fast; be taught quickly“8 – these slogans summarize the significance of understanding the sector and the suitability of implementing lean principles alongside the whole software improvement course of. Only when the entire lean principles are applied collectively, mixed with robust „frequent sense“ with respect to the working environment, is there a foundation for achievement in software program development. In the period of fast technology evolution, it isn’t the largest that survives, but the quickest.

The idea is to do all of this with out sacrificing sources or the well-being of the individuals who make up the development teams that product managers are leading. Lean is just like Agile project administration in that each methodologies improve responsiveness and are oriented towards maximizing customer worth. But, whereas Agile development comes from the world of software program improvement and is especially an iterative method to growth, Lean has its origins in manufacturing. However, the focus of lean growth on the entire value stream, and on streamlining processes, makes it an excellent match for digital and non-digital merchandise alike. The Lean approach presents the lean and agile rules have several advantages, together with improved productiveness, larger buyer satisfaction, reduced waste, and elevated adaptability.

In at present’s quickly evolving software program development panorama, companies are continuously looking for ways to optimize their processes and efficiently deliver high-quality merchandise. One strategy that has gained important traction is Lean Growth Methodology. This article goals to explore the ideas, benefits, and implementation of Lean Improvement, shedding gentle on agile methodology and how it can revolutionize software improvement practices.

Also, this can make the remainder of the employees geared up to organize an equally tasty dish in his absence. In the case of our restaurant instance, one of the primary expectations of the shopper from the standard perspective is „hygiene“ so it is of utmost importance that each one utensils are thoroughly cleaned during which the food will get served. Restaurant administration would like to keep away from any threat on account of „hygiene“, so they opted for a dishwasher machine, thereby, eliminating the potential threat of customer complaints on account of dirty dishes. Each time an individual shuffles between duties, there’s a important time that is required to collect the knowledge, ideas, and get into the model new task. In Accordance to research, it takes a minimum of quarter-hour of concentration to enter flow, and during this time, you aren’t productive.

Lean methodology facilitates an ongoing strategy of incremental adjustment, significantly accelerating product supply by optimizing resources and effort and permitting teams to work efficiently and successfully. The purpose of production is to fabricate merchandise reliably throughout the margins of management. The flow of worth is bodily evident, and the hyperlink between cause and impact is easy to see. For example, suggestions on adjusting the velocity of manufacturing is immediately realized in an increase or decrease in rejected objects. The last point is necessary for organizations and teams to feel like their lean transformation efforts are measurable. Unfortunately, product groups that make the lean leap typically accomplish that as a outcome of they don’t outline the right metrics to measure the transformation course of.

No Comments